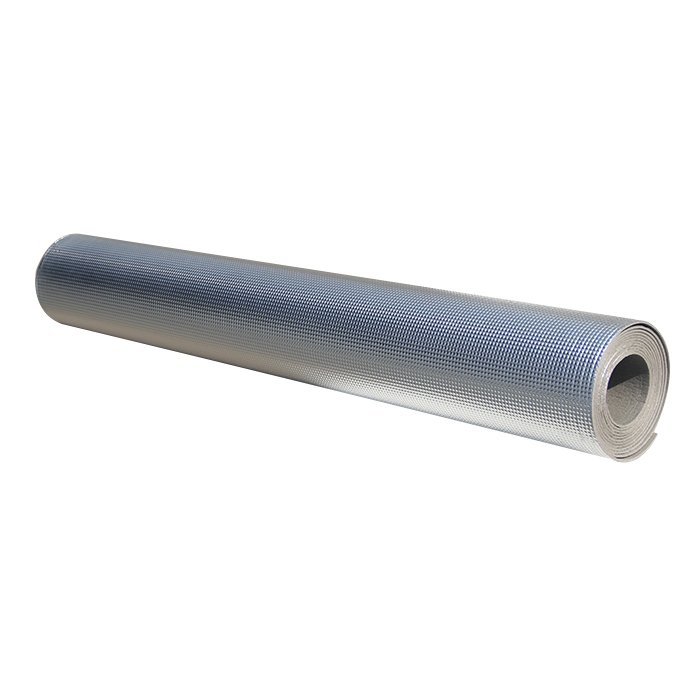

Aluminum foil foam is called so due to it has great insulation properties after Meishuo’s XLEP foam is fire laminated with aluminum foil. From the structures, there are many types of insulation foam because of various of insulation materials, such as metallized film aluminum foil, fireproof woven foil, gridding cloth aluminum foil and fiberglass foil, after single side or double side lamination, Meishuo’s XLPE foam insulate thermal heating transfer, and prevent the radiation flow. Installing reflective aluminum foil between the heat source (sun) and the existing insulation material will increase the efficiency of the R-rated insulation. What’s more, most of pure aluminum foil has excellent fire resistance, which can meet the AS/NZ standard. Due to the foam is closed cell, it better reduce noise and provide a quiet and comfortable environment (refer to the building and construction application). The light weight insulation foam can be easily carried by workers to install on the high place, such as roof and wall, cooperated with proper installation methods, Meishuo’s insulation foam helps to save labor cost largely.