Llámenos 24 horas al día, 7 días a la semana

+86 130 5991 3207Envíenos un correo

info@msfoam.com

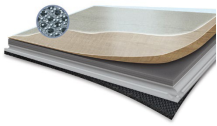

XPE FOAM MSX10

La espuma XPE (material de espuma de polietileno químicamente reticulado) está hecha de resina de polietileno, agente espumante y otros materiales de relleno tras ser extruida uniformemente y luego espumada a alta temperatura. La espuma XPE tiene excelentes características como impermeabilidad, resistencia a la humedad, amortiguación, rebote, conservación del calor, aislamiento térmico, resistencia a la intemperie, resistencia al envejecimiento, resistencia a la corrosión, peso ligero, fácil procesamiento y conformado.

Escenarios de aplicación para el XPE, indicadores especiales de rendimiento y requisitos de parámetros para este producto, y procesos implicados en estos escenarios de aplicación:

Propiedades físicas básicas:

| Parámetro | Rango de valores típicos | Norma de ensayo | Función |

|---|---|---|---|

| Densidad | 60-120 kg/m³ | ISO 845 | Equilibrio entre ligereza y resistencia |

| Espesor | 1,0-3,0 mm | ISO 23529 | Adaptarse al hueco de la chapa de la puerta |

| Resistencia a la tracción | ≥1,5 MPa | ISO 527-3 | Evitan desgarros durante la instalación o el uso |

| Alargamiento a la rotura | ≥150% | ISO 527-3 | Deformación de la superficie de la puerta |

Resistencia al agua y al medio ambiente

| Parámetro | Rango de valores típicos | Norma de ensayo |

|---|---|---|

| Velocidad de transmisión del vapor de agua | <0,05 g/(m²-24h) | ASTM E96 |

| Contenido de célula cerrada | ≥95% | ASTM D6226 |

| Rango de resistencia a la temperatura | -40℃~120℃ | ISO 6722 |

| Resistencia al aceite (empapado en aceite de motor) | Tasa de cambio de volumen <2% | ISO 1817 |

Adherencia y rendimiento del proceso

| Parámetro | Rango de valores típicos | Norma de ensayo |

|---|---|---|

| Resistencia al pelado (con chapa) | ≥1,2 N/mm | ASTM D903 |

| Clasificación ignífuga | UL94 HF-1 o GB 8410 | UL94/GB 8410 |

| Emisión de COV | Cumplen las normas de las fábricas de automóviles (por ejemplo, PV 3341) | VDA 278 |

Proceso de fabricación: Conformado al vacío

Propiedades físicas:

| Parámetros de rendimiento | Valor típico | Norma de ensayo | Techo Adaptabilidad Descripción |

|---|---|---|---|

| Densidad | 60-120 kg/m³ | ISO 845 | Baja densidad (60-80 kg/m³) para ligereza, alta densidad (80-120 kg/m³) para mayor rigidez |

| Espesor | 5-15 mm | Medición real | Regular 8-10 mm (equilibrio entre aislamiento acústico y ocupación de espacio) |

| Resistencia a la tracción | 0,8-2,5 MPa | ISO 527 | Evitar el hundimiento de la piel del techo |

| Alargamiento a la rotura | 100-300% | ISO 527 | Adaptación al modelado de superficies curvas de techo |

| Resistencia a la compresión | 30-100 kPa (compresión 50%) | ISO 604 | Soporta la estructura del techo, resiste la compresión y la deformación |

| Conductividad térmica | 0,035-0,045 W/(m-K) | ISO 8301 | Aislamiento térmico mejor que el EPE |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ para corto plazo) | ASTM D746 | Se adapta a las altas temperaturas del techo del coche en verano |

| Ignifugación | UL94 HF-1 / GB 8410 | UL94 / Norma nacional | Velocidad de combustión vertical ≤100mm/min |

| Absorción de agua | ≤1.0% (24h) | ISO 2896 | Estructura de celdas cerradas para evitar la humedad y el moho |

| Emisión de COV | Formaldehído ≤100μg/m³ | VDA 270 | Necesidad de cumplir las normas de calidad del aire de los fabricantes de automóviles |

Proceso de fabricación: Moldeo por prensado en caliente

Propiedades físicas:

| Parámetros de rendimiento | Valor típico | Norma de ensayo | Descripción de la adaptabilidad de los envases de té |

|---|---|---|---|

| Densidad | 25-60 kg/m³ | ISO 845 | Baja densidad (25-40 kg/m³) para mayor ligereza y portabilidad; alta densidad (40-60 kg/m³) para mayor protección |

| Espesor | 2-10 mm | Medición real | Regular 3-5mm (equilibrando la amortiguación y la ocupación de espacio) |

| Resistencia a la tracción | 0,5-1,5 MPa | ISO 527 | Evitan desgarros durante el transporte |

| Alargamiento a la rotura | 100-250% | ISO 527 | Elasticidad para adaptarse a la forma de las latas de té |

| Set de compresión | ≤15% (compresión 50%, 22h) | ISO 1856 | Buena recuperación tras una compresión prolongada |

| Conductividad térmica | 0,035-0,045 W/(m-K) | ISO 8301 | Aislamiento térmico moderado para evitar cambios bruscos de temperatura |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ para corto plazo) | ASTM D746 | Adaptarse a la cadena de frío y al almacenamiento a altas temperaturas |

| Absorción de agua | ≤0,5% (24h) | ISO 2896 | Estructura de célula cerrada a prueba de humedad para mantener el té seco |

| Emisión de COV | Formaldehído ≤50μg/m³ | GB 4806.7 | Seguridad en contacto con alimentos |

| Respeto del medio ambiente | Reciclable, sin plastificantes | FDA 21 CFR 177.1520 | Cumplir las normas de higiene de los envases de té |

Proceso de fabricación: Troquelado

Propiedades físicas:

| Parámetro de rendimiento | Valor típico | Norma de ensayo | Aislamiento de tuberías Adaptabilidad Descripción |

|---|---|---|---|

| Densidad | 30-100 kg/m³ | ISO 845 | Baja densidad (30-50kg/m³) para tubos ligeros; alta densidad (60-100kg/m³) para tubos de alta temperatura/alta presión |

| Espesor | 10-50 mm | ASTM C518 | Estándar 20-30 mm (para tubos de baja temperatura); más grueso para tubos de alta temperatura |

| Conductividad térmica | 0,032-0,040 W/(m-K) | ISO 8301 | Mejor que el EPE (0,045-0,055), similar al caucho-plástico (0,034-0,038) |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ a corto plazo) | ASTM D746 | Adecuado para tuberías HVAC estándar (agua refrigerada ≤7℃, agua caliente ≤85℃). |

| Resistencia a la tracción | 0,8-2,0 MPa | ISO 527 | Evita el desgarro de la instalación; resistencia a la tracción longitudinal ≥1,5MPa. |

| Contenido de célula cerrada | ≥90% | ASTM D6226 | La elevada estructura de celdas cerradas garantiza la impermeabilidad y la resistencia a la humedad |

| Ignifugación | Clase B1 (GB 8624) | GB/T 8626 | Autoextinguible, índice de oxígeno ≥32% |

| Absorción de agua | ≤1.0% (24h) | ISO 2896 | Resistencia a la humedad a largo plazo, evita la penetración de condensado |

| Emisión de COV | Formaldehído ≤50μg/m³ | GB/T 29899 | Cumple los requisitos de calidad del aire interior |

Proceso de fabricación: Estampación

Propiedades físicas:

| Parámetro de rendimiento | Valor típico | Norma de ensayo | Descripción de la adaptabilidad de la alfombrilla |

|---|---|---|---|

| Densidad | 50-150 kg/m³ | ISO 845 | Baja densidad (50-80 kg/m³) para un uso ligero; alta densidad (100-150 kg/m³) para una gran durabilidad |

| Espesor | 5-20 mm | Medición real | 5-10 mm para uso doméstico; 10-20 mm para aplicaciones comerciales |

| Resistencia a la tracción | 0,8-2,5 MPa | ISO 527 | Resistencia al desgarro para una mayor vida útil |

| Alargamiento a la rotura | 100-300% | ISO 527 | Gran elasticidad para una pisada cómoda |

| Set de compresión | ≤15% (compresión 50%, 22h) | ISO 1856 | Buena resistencia a la compresión a largo plazo |

| Conductividad térmica | 0,035-0,045 W/(m-K) | ISO 8301 | Aislamiento térmico moderado para el calor invernal |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ a corto plazo) | ASTM D746 | Adecuado para suelos radiantes (≤60℃) |

| Resistencia al deslizamiento | Coeficiente de fricción estática ≥0,6 | ASTM D1894 | Superficie en relieve o capa antideslizante compuesta |

| Absorción de agua | ≤1.0% (24h) | ISO 2896 | Estructura de célula cerrada para resistir la humedad y facilitar la limpieza |

| Emisión de COV | Formaldehído ≤50μg/m³ | GB/T 29899 | Cumple las normas de protección del medio ambiente en interiores |

| Respeto del medio ambiente | Reciclable, sin plastificantes | RoHS / REACH | Certificado SGS |

Proceso de fabricación: Estampación

Propiedades físicas:

| Parámetro de rendimiento | Valor típico | Norma de ensayo | Descripción de la adaptabilidad de la esterilla de yoga |

|---|---|---|---|

| Densidad | 50-120 kg/m³ | ISO 845 | Baja densidad (50-80 kg/m³) para portabilidad; alta densidad (80-120 kg/m³) para mayor soporte |

| Espesor | 3-15 mm | Medición real | 8-10 mm para principiantes; 3-6 mm para profesionales |

| Resistencia a la tracción | 0,8-2,5 MPa | ISO 527 | Resistencia al desgarro para una mayor vida útil |

| Alargamiento a la rotura | 100-300% | ISO 527 | Gran elasticidad para adaptarse a movimientos de gran amplitud |

| Set de compresión | ≤15% (compresión 50%, 22h) | ISO 1856 | No es fácil de colapsar tras un uso prolongado |

| Tasa de rebote | ≥50% | ASTM D3574 | Proporcionar estabilidad de movimiento |

| Resistencia al deslizamiento | Coeficiente de fricción estática ≥0,6 | ASTM D1894 | Superficie en relieve o capa antideslizante compuesta |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ a corto plazo) | ASTM D746 | Se adaptan a las diferencias de temperatura interior y exterior |

| Absorción de agua | ≤1.0% (24h) | ISO 2896 | Estructura de célula cerrada para evitar el sudor y el moho |

| Emisión de COV | Formaldehído ≤50μg/m³ | GB/T 29899 | Cumplen las normas de protección del medio ambiente en interiores |

| Respeto del medio ambiente | Reciclable, sin plastificantes | RoHS / REACH | Certificado SGS |

Proceso de fabricación: Moldeo

Propiedades físicas:

| Parámetro de rendimiento | Valor típico | Norma de ensayo | Descripción de la adaptabilidad de los equipos de protección deportiva |

|---|---|---|---|

| Densidad | 60-200 kg/m³ | ISO 845 | Baja densidad (60-100kg/m³) para un diseño ligero; alta densidad (120-200kg/m³) para una gran resistencia al impacto |

| Espesor | 5-30 mm | Medición real | 10-20 mm para rodilleras/codobilleras; 20-30 mm para espinilleras |

| Resistencia a la tracción | 1,0-3,0 MPa | ISO 527 | Evita el desgarro durante las actividades deportivas, alta durabilidad |

| Alargamiento a la rotura | 150-350% | ISO 527 | Gran elasticidad para adaptarse a los movimientos articulares |

| Resistencia a la compresión | 50-200 kPa (compresión 50%) | ISO 604 | Absorbe la energía del impacto (por ejemplo, amortiguación de caídas) |

| Tasa de rebote | ≥60% | ASTM D3574 | Rápida recuperación de la forma para una protección continua |

| Resistencia a la temperatura | -40℃~+85℃ (105℃ a corto plazo) | ASTM D746 | Resiste las variaciones de temperatura exterior |

| Absorción de agua | ≤1.0% (24h) | ISO 2896 | La estructura de célula cerrada resiste el sudor y el olor |

| Emisión de COV | Formaldehído ≤50μg/m³ | GB/T 29899 | Seguro para el contacto directo con la piel |

| Respeto del medio ambiente | Reciclable, sin plastificantes | RoHS / REACH | Certificado SGS |

Proceso de fabricación: Moldeo por compresión