Rufen Sie uns 24/7 an

+86 130 5991 3207Senden Sie uns Post

info@msfoam.com

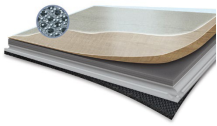

XPE-SCHAUMSTOFF MSX10

XPE-Schaum (chemisch vernetzter Polyethylenschaumstoff) wird aus Polyethylenharz, Schaummittel und anderen Füllstoffen hergestellt, nachdem er gleichmäßig extrudiert und dann bei hoher Temperatur aufgeschäumt wurde. XPE-Schaum hat hervorragende Eigenschaften wie wasserdicht, feuchtigkeitsbeständig, dämpfend, rückfedernd, wärmeerhaltend, wärmeisolierend, witterungsbeständig, alterungsbeständig, korrosionsbeständig, leicht, einfach zu verarbeiten und zu formen.

Anwendungsszenarien für XPE, spezielle Leistungsindikatoren und Parameteranforderungen für dieses Produkt sowie die mit diesen Anwendungsszenarien verbundenen Prozesse:

Grundlegende physikalische Eigenschaften:

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 60-120 kg/m³ | ISO 845 | Gleichgewicht zwischen Leichtgewicht und Stärke |

| Dicke | 1,0-3,0 mm | ISO 23529 | Anpassung an den Blechspalt der Tür |

| Zugfestigkeit | ≥1,5 MPa | ISO 527-3 | Vermeidung von Rissen bei der Installation oder Verwendung |

| Dehnung beim Bruch | ≥150% | ISO 527-3 | Verformung der Türoberfläche |

Wasserdicht und umweltbeständig

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Wasserdampf-Transmissionsrate | <0,05 g/(m²-24h) | ASTM E96 |

| Geschlossene Zellen Inhalt | ≥95% | ASTM D6226 |

| Temperatur-Widerstandsbereich | -40℃~120℃ | ISO 6722 |

| Ölbeständigkeit (in Motoröl getränkt) | Volumenänderungsrate <2% | ISO 1817 |

Adhäsion und Prozessleistung

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Schälfestigkeit (mit Blech) | ≥1,2 N/mm | ASTM D903 |

| Flammenhemmende Bewertung | UL94 HF-1 oder GB 8410 | UL94/GB 8410 |

| VOC-Emissionen | Erfüllen die Normen der Automobilhersteller (z. B. PV 3341) | VDA 278 |

Herstellungsverfahren: Vakuumverformung

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Anpassungsfähigkeit der Decke Beschreibung |

|---|---|---|---|

| Dichte | 60-120 kg/m³ | ISO 845 | Geringe Dichte (60-80kg/m³) für geringes Gewicht, hohe Dichte (80-120kg/m³) für erhöhte Steifigkeit |

| Dicke | 5-15 mm | Tatsächliche Messung | Regulär 8-10 mm (Ausgleich zwischen Schalldämmung und Platzbedarf) |

| Zugfestigkeit | 0,8-2,5 MPa | ISO 527 | Verhindern, dass die Deckenhaut zusammenfällt |

| Dehnung beim Bruch | 100-300% | ISO 527 | Modellierung von gekrümmten Oberflächen an der Decke |

| Druckfestigkeit | 30-100 kPa (50% Druck) | ISO 604 | Stützt die Deckenstruktur, widersteht Druck und Verformung |

| Wärmeleitfähigkeit | 0,035-0,045 W/(m-K) | ISO 8301 | Bessere Wärmedämmleistung als EPE |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ für kurze Zeit) | ASTM D746 | Anpassung an hohe Temperaturen auf dem Autodach im Sommer |

| Schwerentflammbarkeit | UL94 HF-1 / GB 8410 | UL94 / Nationale Norm | Vertikale Brenngeschwindigkeit ≤100mm/min |

| Wasserabsorption | ≤1,0% (24h) | ISO 2896 | Geschlossenzellige Struktur zum Schutz vor Feuchtigkeit und Schimmelbefall |

| VOC-Emissionen | Formaldehyd ≤100μg/m³ | VDA 270 | Notwendigkeit, die Luftqualitätsnormen der Automobilhersteller zu erfüllen |

Herstellungsverfahren: Heißpressverfahren

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Beschreibung der Anpassungsfähigkeit für Teeverpackungen |

|---|---|---|---|

| Dichte | 25-60 kg/m³ | ISO 845 | Geringe Dichte (25-40kg/m³) für Leichtigkeit und Tragbarkeit; hohe Dichte (40-60kg/m³) für erhöhten Schutz |

| Dicke | 2-10 mm | Tatsächliche Messung | Regelmäßig 3-5mm (Ausgleich zwischen Pufferung und Platzbedarf) |

| Zugfestigkeit | 0,5-1,5 MPa | ISO 527 | Verhindern das Reißen beim Transport |

| Dehnung beim Bruch | 100-250% | ISO 527 | Elastizität zur Anpassung an die Form von Teedosen |

| Druckverformungsrest | ≤15% (50% Kompression, 22h) | ISO 1856 | Gute Erholung nach Langzeitkompression |

| Wärmeleitfähigkeit | 0,035-0,045 W/(m-K) | ISO 8301 | Mäßige Wärmedämmung zur Vermeidung plötzlicher Temperaturschwankungen |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ für kurze Zeit) | ASTM D746 | Anpassung an die Kühlkette und Hochtemperaturlagerung |

| Wasserabsorption | ≤0,5% (24h) | ISO 2896 | Geschlossenzellige Struktur zum Schutz vor Feuchtigkeit, damit der Tee trocken bleibt |

| VOC-Emissionen | Formaldehyd ≤50μg/m³ | GB 4806.7 | Sicherheit im Kontakt mit Lebensmitteln |

| Umweltfreundlichkeit | Recycelbar, ohne Weichmacher | FDA 21 CFR 177.1520 | Einhaltung der Hygienestandards für Teeverpackungen |

Herstellungsprozess: Stanzen

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Anpassungsfähigkeit der Rohrdämmung Beschreibung |

|---|---|---|---|

| Dichte | 30-100 kg/m³ | ISO 845 | Geringe Dichte (30-50kg/m³) für leichte Rohre; hohe Dichte (60-100kg/m³) für Hochtemperatur-/Hochdruckrohre |

| Dicke | 10-50 mm | ASTM C518 | Standard 20-30mm (für Niedertemperaturrohre); dicker für Hochtemperaturrohre |

| Wärmeleitfähigkeit | 0,032-0,040 W/(m-K) | ISO 8301 | Besser als EPE (0,045-0,055), ähnlich wie Gummi/Kunststoff (0,034-0,038) |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ kurzfristig) | ASTM D746 | Geeignet für Standard-HKL-Rohre (Kaltwasser ≤7℃, Warmwasser ≤85℃) |

| Zugfestigkeit | 0,8-2,0 MPa | ISO 527 | Verhindert das Reißen der Installation; Längszugfestigkeit ≥1,5MPa |

| Geschlossene Zellen Inhalt | ≥90% | ASTM D6226 | Hohe geschlossenzellige Struktur gewährleistet Wasserdichtigkeit und Feuchtigkeitsbeständigkeit |

| Schwerentflammbarkeit | Klasse B1 (GB 8624) | GB/T 8626 | Selbstverlöschend, Sauerstoffindex ≥32% |

| Wasserabsorption | ≤1,0% (24h) | ISO 2896 | Langfristige Feuchtigkeitsbeständigkeit, verhindert das Eindringen von Kondensat |

| VOC-Emissionen | Formaldehyd ≤50μg/m³ | GB/T 29899 | Erfüllt die Anforderungen an die Luftqualität in Innenräumen |

Herstellungsprozess: Prägen

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Bodenmatte Anpassungsfähigkeit Beschreibung |

|---|---|---|---|

| Dichte | 50-150 kg/m³ | ISO 845 | Geringe Dichte (50-80kg/m³) für leichtes Gewicht; hohe Dichte (100-150kg/m³) für hohe Haltbarkeit |

| Dicke | 5-20 mm | Tatsächliche Messung | 5-10 mm für den Hausgebrauch; 10-20 mm für gewerbliche Anwendungen |

| Zugfestigkeit | 0,8-2,5 MPa | ISO 527 | Reißfestigkeit für eine längere Nutzungsdauer |

| Dehnung beim Bruch | 100-300% | ISO 527 | Hohe Elastizität für bequemen Tritt |

| Druckverformungsrest | ≤15% (50% Kompression, 22h) | ISO 1856 | Gutes Rückstellvermögen nach Langzeitkompression |

| Wärmeleitfähigkeit | 0,035-0,045 W/(m-K) | ISO 8301 | Mäßige Wärmeisolierung für Wärme im Winter |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ kurzfristig) | ASTM D746 | Geeignet für Fußbodenheizungen (≤60℃) |

| Rutschfestigkeit | Haftreibungskoeffizient ≥0,6 | ASTM D1894 | Oberflächenprägung oder rutschhemmende Verbundschicht |

| Wasserabsorption | ≤1,0% (24h) | ISO 2896 | Geschlossenzellige Struktur für Feuchtigkeitsbeständigkeit und einfache Reinigung |

| VOC-Emissionen | Formaldehyd ≤50μg/m³ | GB/T 29899 | Erfüllt die Normen zum Schutz der Umwelt in Innenräumen |

| Umweltfreundlichkeit | Recycelbar, weichmacherfrei | RoHS / REACH | SGS-zertifiziert |

Herstellungsprozess: Prägen

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Yogamatte Anpassungsfähigkeit Beschreibung |

|---|---|---|---|

| Dichte | 50-120 kg/m³ | ISO 845 | Geringe Dichte (50-80kg/m³) für Tragbarkeit; hohe Dichte (80-120kg/m³) für besseren Halt |

| Dicke | 3-15 mm | Tatsächliche Messung | 8-10 mm für Anfänger; 3-6 mm für Profis |

| Zugfestigkeit | 0,8-2,5 MPa | ISO 527 | Reißfestigkeit für eine längere Nutzungsdauer |

| Dehnung beim Bruch | 100-300% | ISO 527 | Hohe Elastizität zur Anpassung an weiträumige Bewegungen |

| Druckverformungsrest | ≤15% (50% Kompression, 22h) | ISO 1856 | Nicht leicht zusammenzubrechen nach längerem Gebrauch |

| Rückprallrate | ≥50% | ASTM D3574 | Bewegungsstabilität bieten |

| Rutschfestigkeit | Haftreibungskoeffizient ≥0,6 | ASTM D1894 | Oberflächenprägung oder rutschhemmende Verbundschicht |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ kurzfristig) | ASTM D746 | Anpassung an Innen- und Außentemperaturunterschiede |

| Wasserabsorption | ≤1,0% (24h) | ISO 2896 | Geschlossenzellige Struktur zur Vermeidung von Schweiß und Schimmel |

| VOC-Emissionen | Formaldehyd ≤50μg/m³ | GB/T 29899 | Erfüllt die Normen für den Umweltschutz in Innenräumen |

| Umweltfreundlichkeit | Recycelbar, weichmacherfrei | RoHS / REACH | SGS-zertifiziert |

Herstellungsverfahren: Gießen

Physikalische Eigenschaften:

| Leistungsparameter | Typischer Wert/Bereich | Test Standard | Sportschutzausrüstung Anpassungsfähigkeit Beschreibung |

|---|---|---|---|

| Dichte | 60-200 kg/m³ | ISO 845 | Geringe Dichte (60-100kg/m³) für Leichtbauweise; hohe Dichte (120-200kg/m³) für hohe Schlagfestigkeit |

| Dicke | 5-30 mm | Tatsächliche Messung | 10-20 mm für Knie-/Ellbogenschützer; 20-30 mm für Schienbeinschützer |

| Zugfestigkeit | 1,0-3,0 MPa | ISO 527 | Verhindert das Reißen bei sportlichen Aktivitäten, hohe Haltbarkeit |

| Dehnung beim Bruch | 150-350% | ISO 527 | Hohe Elastizität zur Anpassung an Gelenkbewegungen |

| Druckfestigkeit | 50-200 kPa (50% Druck) | ISO 604 | Absorbiert Aufprallenergie (z. B. Sturzdämpfung) |

| Rückprallrate | ≥60% | ASTM D3574 | Schnelle Formerholung für kontinuierlichen Schutz |

| Temperaturbeständigkeit | -40℃~+85℃ (105℃ kurzfristig) | ASTM D746 | Widersteht Temperaturschwankungen im Freien |

| Wasserabsorption | ≤1,0% (24h) | ISO 2896 | Geschlossenzellige Struktur schützt vor Schweiß und Geruch |

| VOC-Emissionen | Formaldehyd ≤50μg/m³ | GB/T 29899 | Sicher bei direktem Hautkontakt |

| Umweltfreundlichkeit | Recycelbar, weichmacherfrei | RoHS / REACH | SGS-zertifiziert |

Herstellungsverfahren: Formpressen