Rufen Sie uns 24/7 an

+86 130 5991 3207Senden Sie uns Post

info@msfoam.com

IXPE-SCHAUMSTOFF MSI05

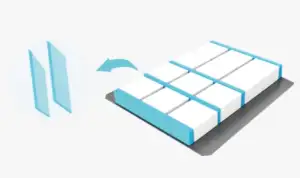

IXPE-Schaum wird mittels Elektronenstrahlvernetzungstechnologie entwickelt und hergestellt. Das Polyethylen wird mit einem Elektronenstrahl bestrahlt, erhitzt und 5 bis 40 Mal aufgeschäumt, um einen plattenförmigen Hochschaum zu bilden. IXPE-Schaumstoff zeichnet sich durch eine nahezu 100% geschlossene Zellstruktur aus, die sich durch geringes Gewicht und hohe Steifigkeit auszeichnet und viele hervorragende Eigenschaften wie Wärmedämmung, Polsterung, Hitzebeständigkeit und Flammwidrigkeit aufweist.

Anwendungsszenarien für IXPE, spezielle Leistungsindikatoren und Parameteranforderungen für dieses Produkt sowie die mit diesen Anwendungsszenarien verbundenen Prozesse:

Grundlegende physikalische Eigenschaften:

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 60-120 kg/m³ | ISO 845 | Gleichgewicht zwischen Leichtgewicht und Stärke |

| Dicke | 1,0-3,0 mm | ISO 23529 | Anpassung an die Blechspalte der Tür |

| Zugfestigkeit | ≥1,5 MPa | ISO 527-3 | Vermeidung von Rissen bei der Installation oder Verwendung |

| Dehnung beim Bruch | ≥150% | ISO 527-3 | Anpassung an die gekrümmte Verformung der Türflächen |

Wasserdicht und umweltbeständig

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Wasserdampf-Transmissionsrate | <0,05 g/(m²-24h) | ASTM E96 |

| Geschlossene Zellen Inhalt | ≥95% | ASTM D6226 |

| Temperatur-Widerstandsbereich | -40℃~120℃ | ISO 6722 |

| Ölbeständigkeit (Eintauchen in Motoröl) | Volumenänderungsrate <2% | ISO 1817 |

Adhäsion und Prozessleistung

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Schälfestigkeit (mit Blech) | ≥1,2 N/mm | ASTM D903 |

| Flammenhemmende Bewertung | UL94 HF-1 oder GB 8410 | UL94/GB 8410 |

| VOC-Emissionen | Erfüllen die Normen der Automobilhersteller (z. B. PV 3341) | VDA 278 |

Herstellungsverfahren: Vakuumverformung

Leistungsparameter:

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 80-150 kg/m³ | ISO 845 | Gleichgewicht zwischen Stärke und Leichtgewicht |

| Dicke | 5-20 mm | ISO 23529 | Entspricht dem strukturellen Aufbau der Instrumententafel |

| Druckfestigkeit (25%) | 100-500 kPa | ISO 844 | Beständigkeit gegen langfristige Druckverformung |

| Zugfestigkeit | ≥1,8 MPa | ISO 527-3 | Vermeidung von Rissen bei der Installation oder Verwendung |

Wärme- und Wetterbeständigkeit

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Langfristige Temperaturbeständigkeit | -40℃~120℃ | ISO 6722 |

| Kurzzeitige Spitzentemperaturbeständigkeit | ≤140℃ (direktes Sonnenlicht) | SAE J2412 |

| Wärmeverformung Temperatur (0,45MPa) | ≥110℃ | ASTM D648 |

| Alterung in feuchter Wärme (85℃/85% RH, 1000h) | Keine Rissbildung, keine Schrumpfung | GB/T 2423.4 |

Akustische Leistung (Schalldämmung/Schockabsorption)

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Schalldämmung (500-2000Hz) | ≥30 dB | ISO 10140-2 |

| Schallabsorptionskoeffizient (1kHz) | ≥0.6 | ASTM E1050 |

| Dämpfungsfaktor (tanδ) | 0.1-0.3 | DMA-Test (ISO 6721) |

Sicherheit und Umweltschutz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Flammenhemmende Bewertung | UL94 HF-1 oder GB 8410 | UL94/GB 8410 |

| VOC-Emissionen | Gesamtkohlenstoffflüchtigkeit ≤50 μgC/g | VDA 278 |

| Fogging-Wert | ≤2 mg (Glanzmethode) | DIN 75201 |

Herstellungsverfahren: Vakuumverformung

Pufferung und mechanische Eigenschaften

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 30-80 kg/m³ | ISO 845 | Gleichgewicht zwischen Leichtgewicht und Energieabsorption |

| Druckfestigkeit (50%) | 50-300 kPa | ISO 844 | Widerstandsfähigkeit gegen Verformung bei mehrfachen Stößen |

| Rückprallrate | ≥85% | ASTM D3574 | Wiederverwendbarkeit |

| Energie-Absorptionsrate | ≥70% (Falltest) | ISTA 3A | Kern-Anti-Schock-Index |

Umweltresistenz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Temperatur-Widerstandsbereich | -50℃~100℃ | ASTM D3575 |

| Beständigkeit gegen feuchte Wärme (70℃/95% RH, 48h) | Keine Verformung, kein Schimmel | GB/T 4857.12 |

| Ölbeständigkeit (bei Kontakt mit Schmieröl) | Gewichtsänderungsrate <1% | ISO 1817 |

Sicherheit und Umweltschutz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Elektrostatischer Schutz | Oberflächenwiderstand 10⁶-10⁹ Ω | ANSI/ESD S20.20 |

| VOC-Emissionen | Gesamtkohlenstoffflüchtigkeit ≤20 μgC/g | VDA 278 |

| Wiederverwertbarkeit | 100% wiederverwendbar | ISO 15270 |

Herstellungsprozess: Stanzen

Pufferung und mechanische Eigenschaften

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 30-80 kg/m³ | ISO 845 | Gleichgewicht zwischen Leichtgewicht und Energieabsorption |

| Druckfestigkeit (50%) | 50-300 kPa | ISO 844 | Widerstandsfähigkeit gegen Verformung bei mehrfachen Stößen |

| Rückprallrate | ≥85% | ASTM D3574 | Wiederverwendbarkeit |

| Energie-Absorptionsrate | ≥70% (Falltest) | ISTA 3A | Kern-Anti-Schock-Index |

Umweltresistenz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Temperatur-Widerstandsbereich | -50℃~100℃ | ASTM D3575 |

| Beständigkeit gegen feuchte Wärme (70℃/95% RH, 48h) | Keine Verformung, kein Schimmel | GB/T 4857.12 |

| Ölbeständigkeit (bei Kontakt mit Schmieröl) | Gewichtsänderungsrate <1% | ISO 1817 |

Sicherheit und Umweltschutz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Elektrostatischer Schutz | Oberflächenwiderstand 10⁶-10⁹ Ω | ANSI/ESD S20.20 |

| VOC-Emissionen | Gesamtkohlenstoffflüchtigkeit ≤20 μgC/g | VDA 278 |

| Wiederverwertbarkeit | 100% wiederverwendbar | ISO 15270 |

Herstellungsprozess: Stanzen

Grundlegende physikalische Eigenschaften

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 50-120 kg/m³ | ISO 845 | Weichheit und Haltbarkeit beeinflussen |

| Dicke | 3-10 mm | ISO 23529 | Übliche Yogamattenstärke (5-8 mm) |

| Zugfestigkeit | ≥1,0 MPa | ISO 527-3 | Verhindern Sie Risse oder Verformungen |

| Dehnung beim Bruch | ≥150% | ISO 527-3 | Verbesserung der Flexibilität |

| Druckverformungsrest (22h, 50%) | ≤10% | ISO 1856 | Nicht leicht zusammenzubrechen nach längerem Gebrauch |

Komfort und Funktionalität

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Rückprallrate | ≥85% | ASTM D3574 |

| Rutschhemmung (trocken/nass) | Haftreibungskoeffizient ≥0,6 | ASTM D1894 |

| Wasserabsorption | <1% | ASTM D570 |

| Härte (Shore C) | 40-70 | ISO 868 |

Sicherheit und Umweltschutz

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| VOC-Emissionen | Entspricht der EN 71-3 | VDA 278 |

| Hautreizung | Keine Reizung (ISO 10993) | Biokompatibilitätstest |

| Wiederverwertbarkeit | 100% wiederverwendbar | ISO 15270 |

Herstellungsverfahren: Gießen

Grundlegende physikalische Eigenschaften

| Parameter | Typischer Wertebereich | Test Standard | Funktion |

|---|---|---|---|

| Dichte | 20-80 kg/m³ | ISO 845 | Ultraleichtgewicht (40%+ leichter als herkömmliche Materialien) |

| Dicke | 5-50 mm | ISO 23529 | Anpassung an den Raum der Flugzeugstruktur |

| Druckfestigkeit (10%) | 50-300 kPa | ISO 844 | Widerstandsfähig gegen Verformung durch Luftstromdruck |

| Zugfestigkeit | ≥1,0 MPa | ISO 527-3 | Verhinderung von Rissen bei der Installation oder im Flug |

Thermische und flammhemmende Eigenschaften (Schlüsselindikatoren)

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Langfristige Temperaturbeständigkeit | -70℃~140℃ | RTCA DO-160 |

| Kurzzeitige Spitzentemperaturbeständigkeit | ≤200℃ (Notfallbedingungen) | ABD 0031 |

| Wärmeleitfähigkeit | 0,030-0,040 W/(m-K) | ASTM C518 |

| Grenzsauerstoffindex (LOI) | ≥30% | ASTM D2863 |

| Flammenausbreitungsindex | ≤5 (WEIT 25.853) | FAA Vertikaler Verbrennungstest |

Akustische Eigenschaften und Dauerhaftigkeit

| Parameter | Typischer Wertebereich | Test Standard |

|---|---|---|

| Schalldämmung (500-4000Hz) | ≥35 dB | ISO 10140-2 |

| Alterung in feuchter Hitze (85℃/85% RH, 2000h) | Keine Delamination | ASTM D2126 |

| Beständigkeit gegen Hydrauliköl (Skydrol Immersion) | Ausdehnungsrate <2% | ISO 1817 |

Herstellungsverfahren: Gießen