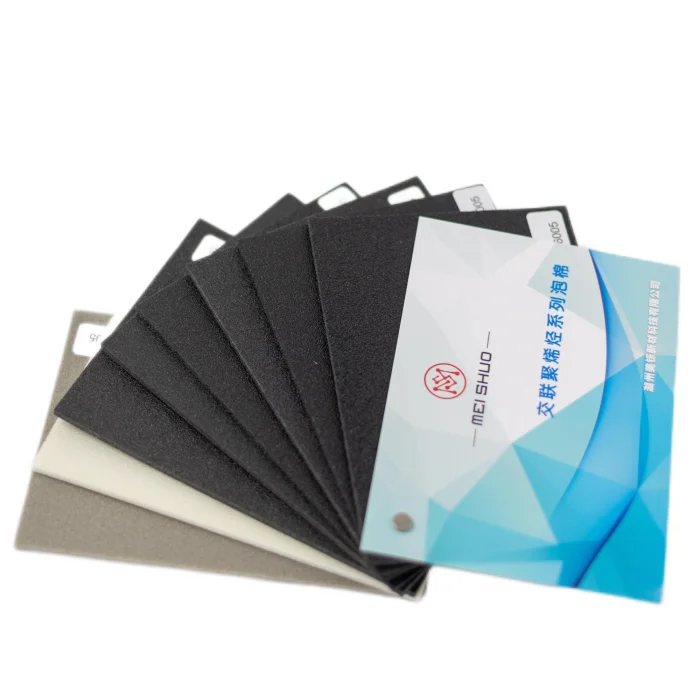

XPE Foam

XPE (Chemical Cross-linked Polyethylene Foam), a new-generation eco-friendly material, is characterized by being non-toxic, odorless, soundproof, waterproof, thermally insulating, highly resilient, and adjustable in softness, thickness, and lightweight—advantages that make it irreplaceable among other foam materials. It supports hot/cold pressing, vacuum forming, lamination, screen printing, die-cutting, and carving, and can be produced in flame-retardant or high-flame-retardant grades. Applications include sports protective gear, handbags, footwear, toys, air conditioning systems, tapes, sports flooring, automotive soft interiors, building insulation, and floor moisture/soundproofing.

- Thermal InsulationIts fine independent bubble structure effectively reduces energy exchange caused by air convection, making it ideal for insulation pipes and boards.Excellent anti-condensation properties suit it for moisture-rich environments like refrigerators, air conditioners, and cold storage.

- SoundproofingCapable of reducing noise and vibration, suitable for sound insulation in aircraft, rail vehicles, automobiles, machinery, and building floors, walls, and ceilings.

- MoldabilityHigh heat resistance and uniform density enable deep drawing via vacuum or thermal forming.Used in automotive interior components (e.g., air conditioning evaporator cabinets, headliners, air ducts, sun visors) and footwear materials.

- CushioningSemi-rigid foam structure retains performance after strong impacts, widely used for packaging precision instruments and semiconductors.Its formability makes it suitable for sports protection and leisure products (e.g., crawling mats, gymnastics mats, protective gear, lawn pads).