Call Us 24/7

+86 130 5991 3207Send Us Mail

info@msfoam.com

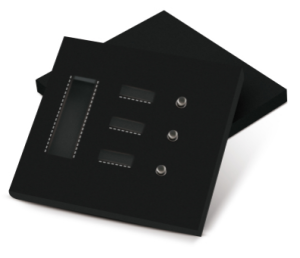

IXPP FOAM MSP25

Foaming multiple: 5–30 times; width: within 600-2000MM thickness: single layer: 1-6 MM, can also be compounded into 2-50MM thickness, commonly used colors: off-white, milky white.

Application scenarios for IXPP, special performance indicators and parameter requirements for this product, and the processes involved in this application scenario:

- Basic Physical Properties:

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 60-120 kg/m³ | ISO 845 | Balance between lightweight and strength |

| Thickness | 1.0-3.0 mm | ISO 23529 | Adapt to door sheet metal gap |

| Tensile Strength | ≥1.5 MPa | ISO 527-3 | Prevent tearing during installation or use |

| Elongation at Break | ≥150% | ISO 527-3 | Fit door surface deformation |

Waterproof and Environmental Resistance Performance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Water Vapor Transmission Rate | <0.05 g/(m²·24h) | ASTM E96 |

| Closed Cell Content | ≥95% | ASTM D6226 |

| Temperature Resistance Range | -40℃~120℃ | ISO 6722 |

| Oil Resistance (soaked in engine oil) | Volume change rate <2% | ISO 1817 |

Adhesion and Process Performance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Peel Strength (with sheet metal) | ≥1.2 N/mm | ASTM D903 |

| Flame Retardant Rating | UL94 HF-1 or GB 8410 | UL94/GB 8410 |

| VOC Emission | Meet automobile factory standards (e.g., PV 3341) | VDA 278 |

Manufacturing Process: Vacuum Forming

Performance Parameters:

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 80-150 kg/m³ | ISO 845 | Balance strength and lightweight |

| Thickness | 5-20 mm | ISO 23529 | Match instrument panel structural design |

| Compressive Strength (25%) | 100-500 kPa | ISO 844 | Resist long-term compression deformation |

| Tensile Strength | ≥1.8 MPa | ISO 527-3 | Prevent tearing during installation or use |

Thermal and Weather Resistance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Long-term Temperature Resistance Range | -40℃~120℃ | ISO 6722 |

| Short-term Peak Temperature Resistance | ≤140℃ (direct sunlight) | SAE J2412 |

| Heat Distortion Temperature (0.45MPa) | ≥110℃ | ASTM D648 |

| Damp Heat Aging (85℃/85% RH, 1000h) | No cracking, no shrinkage | GB/T 2423.4 |

Acoustic Performance (Sound Insulation/Shock Absorption)

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Sound Insulation (500-2000Hz) | ≥30 dB | ISO 10140-2 |

| Sound Absorption Coefficient (1kHz) | ≥0.6 | ASTM E1050 |

| Damping Factor (tanδ) | 0.1-0.3 | DMA Test (ISO 6721) |

Safety and Environmental Protection

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Flame Retardant Rating | UL94 HF-1 or GB 8410 | UL94/GB 8410 |

| VOC Emission | Total Carbon Volatility ≤50 μgC/g | VDA 278 |

| Fogging Value | ≤2 mg (gloss method) | DIN 75201 |

Manufacturing Process: Vacuum Forming

Basic Physical Properties

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 50-100 kg/m³ | ISO 845 | Lightweight (30% lighter than traditional materials) |

| Thickness | 3-10 mm | ISO 23529 | Match the ceiling design space |

| Tensile Strength | ≥1.2 MPa | ISO 527-3 | Prevent tearing during installation or use |

| Compressive Strength (25%) | 80-300 kPa | ISO 844 | Resist long-term compression deformation |

Thermal and Weather Resistance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Long-term Temperature Resistance Range | -40℃~120℃ | ISO 6722 |

| Short-term Peak Temperature Resistance | ≤140℃ (exposure condition) | SAE J2412 |

| Damp Heat Aging (85℃/85% RH, 500h) | No delamination, no deformation | GB/T 2423.4 |

Acoustic and Safety Performance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Sound Insulation (1kHz) | ≥25 dB | ISO 10140-2 |

| Sound Absorption Coefficient (500Hz) | ≥0.5 | ASTM E1050 |

| Flame Retardant Rating | UL94 HF-1 or GB 8410 | UL94/GB 8410 |

| VOC Emission | Total Carbon Volatility ≤30 μgC/g | VDA 278 |

Process Adaptability

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Peel Strength (with fabric) | ≥1.0 N/mm | ASTM D903 |

| Flexural Stiffness | 5-15 N/mm² | ISO 178 |

Manufacturing Process: Hot Press Molding

Physical Properties:Buffering and Mechanical Properties

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 30-80 kg/m³ | ISO 845 | Balance between lightweight and energy absorption |

| Compressive Strength (50%) | 50-300 kPa | ISO 844 | Resistance to deformation under multiple impacts |

| Rebound Rate | ≥85% | ASTM D3574 | Reusability |

| Energy Absorption Rate | ≥70% (drop test) | ISTA 3A | Core anti-shock index |

Environmental Resistance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Temperature Resistance Range | -50℃~100℃ | ASTM D3575 |

| Resistance to Damp Heat (70℃/95% RH, 48h) | No deformation, no mildew | GB/T 4857.12 |

| Oil Resistance (in contact with lubricating oil) | Weight change rate <1% | ISO 1817 |

Safety and Environmental Protection

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Electrostatic Protection | Surface resistance 10⁶-10⁹ Ω | ANSI/ESD S20.20 |

| VOC Emission | Total carbon volatility ≤20 μgC/g | VDA 278 |

| Recyclability | 100% recyclable | ISO 15270 |

Manufacturing Process: Die Cutting

Buffering and Mechanical Properties

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 30-80 kg/m³ | ISO 845 | Balance between lightweight and energy absorption |

| Compressive Strength (50%) | 50-300 kPa | ISO 844 | Resistance to deformation under multiple impacts |

| Rebound Rate | ≥85% | ASTM D3574 | Reusability |

| Energy Absorption Rate | ≥70% (drop test) | ISTA 3A | Core anti-shock index |

Environmental Resistance

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Temperature Resistance Range | -50℃~100℃ | ASTM D3575 |

| Resistance to Damp Heat (70℃/95% RH, 48h) | No deformation, no mildew | GB/T 4857.12 |

| Oil Resistance (in contact with lubricating oil) | Weight change rate <1% | ISO 1817 |

Safety and Environmental Protection

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Electrostatic Protection | Surface resistance 10⁶-10⁹ Ω | ANSI/ESD S20.20 |

| VOC Emission | Total carbon volatility ≤20 μgC/g | VDA 278 |

| Recyclability | 100% recyclable | ISO 15270 |

Manufacturing Process: Die Cutting

Basic Physical Properties

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 50-120 kg/m³ | ISO 845 | Affects softness and durability |

| Thickness | 3-10 mm | ISO 23529 | Common yoga mat thickness (5-8mm) |

| Tensile Strength | ≥1.0 MPa | ISO 527-3 | Prevent tearing or deformation |

| Elongation at Break | ≥150% | ISO 527-3 | Improve flexibility |

| Compression Set (22h, 50%) | ≤10% | ISO 1856 | Not easy to collapse after long-term use |

Comfort and Functionality

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Rebound Rate | ≥85% | ASTM D3574 |

| Slip Resistance (dry/wet) | Static friction coefficient ≥0.6 | ASTM D1894 |

| Water Absorption | <1% | ASTM D570 |

| Hardness (Shore C) | 40-70 | ISO 868 |

Safety and Environmental Protection

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| VOC Emission | Compliant with EN 71-3 | VDA 278 |

| Skin Irritation | No irritation (ISO 10993) | Biocompatibility test |

| Recyclability | 100% recyclable | ISO 15270 |

Manufacturing Process: Molding

Basic Physical Properties

| Parameter | Typical Value Range | Test Standard | Function |

|---|---|---|---|

| Density | 20-80 kg/m³ | ISO 845 | Ultra-lightweight (40%+ lighter than traditional materials) |

| Thickness | 5-50 mm | ISO 23529 | Adapt to airframe structure space |

| Compressive Strength (10%) | 50-300 kPa | ISO 844 | Resist airflow pressure deformation |

| Tensile Strength | ≥1.0 MPa | ISO 527-3 | Prevent tearing during installation or flight |

Thermal and Flame Retardant Properties (Key Indicators)

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Long-term Temperature Resistance Range | -70℃~140℃ | RTCA DO-160 |

| Short-term Peak Temperature Resistance | ≤200℃ (emergency conditions) | ABD 0031 |

| Thermal Conductivity | 0.030-0.040 W/(m·K) | ASTM C518 |

| Limiting Oxygen Index (LOI) | ≥30% | ASTM D2863 |

| Flame Spread Index | ≤5 (FAR 25.853) | FAA Vertical Burn Test |

Acoustic and Durability Properties

| Parameter | Typical Value Range | Test Standard |

|---|---|---|

| Sound Insulation (500-4000Hz) | ≥35 dB | ISO 10140-2 |

| Damp Heat Aging (85℃/85% RH, 2000h) | No delamination | ASTM D2126 |

| Resistance to Hydraulic Oil (Skydrol immersion) | Expansion rate <2% | ISO 1817 |

Manufacturing Process: Molding